At Encon Energy Concepts, we are dedicated to enhancing awareness about the importance of energy efficiency among engineers and engineering students. Our workshops and seminars are designed for both educational institutions and corporate business organizations, focusing on energy efficiency in industrial and commercial buildings.

This seminar addresses various losses and methodologies to correct them in electromechanical utilities, including:

Infrared Thermography: A crucial predictive maintenance tool for a safe, productive, and efficient working environment.

Participants will receive a “Certificate of Participation” from Encon Energy Concepts.

This seminar covers the causes and impacts of harmonics in business environments and methods for their mitigation. The session includes practical understanding with photographs and equipment connected to a load center at your institution.

Participants will receive a “Certificate of Participation” from Encon Energy Concepts.

In addition to our seminars and workshops, we offer advanced training programs conducted by international ISO training and certification bodies, such as SGS India.

Certification of Participation:

Provided to all participants by the certification body.

Certification of Training:

Awarded to participants who pass the examination at the end of the training program.

Training Programs

Training ProgramsWe should remember that every equipment is designed for the Maximum Loading Under worst case Conditions , which is NOT the case in real life situation... Every equipment is losing its Best Efficiency Point due to ageing, Every equipment is to be tuned for the Specific application of your Industry , in order to achieve the best output at lesser operating Cost, Hence we study the Operating Conditions and the Working style of each & every equipment under the Real –Time Conditions , and analyze the necessary solutions , in order to Improve the Efficiency of the Equipment and to reduce the Energy Losses.

What are the Equipments we Study ...?

What are the Equipments we Study ...?

What Is Thermal Audit ..?

What Is Thermal Audit ..?

Thermal Audit is the Study of Efficiency/ Losses of an Industrial Heating System like Boilers & Furnaces.

Why Thermal Audit ..?

Why Thermal Audit ..?

What We Do ...?

What We Do ...?

We analyse the existing Boiler / Furnace Operation

When your business depends on electrical machinery and equipment for increased productivity and improved cash flow, it is extremely important to keep that machinery inspected and well-maintained on a regular basis. Preventive electrical equipment maintenance done regularly by trained, professional and experienced electrical workers helps to detect electrical problems before they become serious issues. By scheduling routine maintenance checks that utilize advanced technology and expert electrical skills, the industrial equipment and machinery on which your business runs can continue working efficiently, reducing the risk of a catastrophic failure that can cost time and money. Read on to learn the benefits of preventive electrical equipment maintenance, as well as the use of infrared thermography in detecting electrical problems.

An effective preventive electrical maintenance program involves scheduling routine inspections and checkups on a regular basis, ensuring that your equipment and machinery is continually checked for both minor and major problems.

Not only can preventive electrical maintenance save businesses time and money, but by keeping equipment functioning properly, the risk of hazard is greatly reduced and the work environment becomes a safer place. Electrical equipment failure can lead to serious hazards, including fires and arc flash, which can leave workers severely injured. Equipment that is not working properly or problems that are left undetected can have unfortunate results for electricians working with or near the equipment. Machinery should be inspected frequently to identify potential problems and prevent them from becoming dangers in the workplace.

The use of infrared (IR) thermography is critical to preventive maintenance in electrical work environments. All objects radiate thermal energy, or heat, and IR cameras can detect the radiation of heat that is emitted from any given object by taking "heat" images. Through a range of colors, these images present hot spots that cannot otherwise be perceived by the naked eye. IR thermograph is used to reveal loose circuits, equipment failure and safety hazards. Electrical workers can then use the thermographic images to analyze and measure temperatures, identifying problems and fixing them before they become severe.

Why Compressed Air Audit...?

Why Compressed Air Audit...?

We all know that ...

We all know how much is the Volume of Compressed Air we need to run our Plant & machineries.... BUT WE SELDOM KNOW HOW MUCH IS BEING DELIVERED FROM OUR COMPRESSORS.

What We do ...?

What We do ...?

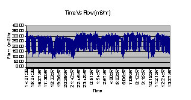

We with our ON-LINE DATALOGGER, capture the Pressure/Velocity/ Temperature and the Volume of Compressed Air that we deliver from The Main Pipe Line ON REAL TIME BASIS, and compares with the Consumption requirement with the Industry Standards, with the Help of a Computer Programme.

Benefits ...

Benefits ...

This Study reveals the real air that is being produced and the Energy/Money Spent on it... This Study also reveals the exact Volume is Compressed Air that is exactly required by the Process in the Real life Operating Conditions.

Accurate Air Volume Generated and , Specific Power Consumption Study, Maximum Utilisation Efficiency of Compressors, Instant Velocity (Max/Min) / Total Flow / Pressure / Temperature Graphs

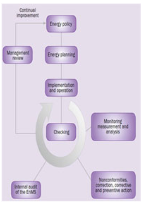

ISO 50001:2011, Energy management systems – Requirements with guidance for use, is a voluntary International Standard developed by ISO (International Organization for Standardization). ISO 50001 gives organizations the requirements for energy management systems(EnMS). Benefits: ISO 50001 provides benefits for organizations large and small, in both public and private sectors, in manufacturing and services, in all regions of the world. ISO 50001 will establish a framework for industrial plants ; commercial, institutional, and governmental facilities; and entire organizations to manage energy. ISO 50001 — Why is it important ?

Energy is critical to organizational operations and can be a major cost to organizations, whatever their activities. An idea can be gained by considering the use of energy through the supply chain of a business, from raw materials through to recycling. ISO 50001 — What will it do ? ISO 50001 will provide public and private sector organizations with management strategies to increase energy efficiency, reduce costs and improve energy performance. ISO 50001 — How does it work ?

ISO 50001 is based on the ISO management system model familiar to more than a million organizations worldwide who implement standards such as ISO 9001 (quality management), ISO 14001 (environmental management), ISO 22000 (food safety), ISO/IEC 27001 (information security). In particular, ISO 50001 follows the Plan-Do-Check-Act process for continual improvement of the energy management system.

Approach:

Plan:

conduct the energy review and establish the baseline, energy performance indicators (EnPIs), objectives, targets and action plans necessary to deliver results in accordance with opportunities to improve energy performance and the organization’s energy policy.

Do:

implement the energy management action plans

Check :

monitor and measure processes and the key characteristics of its operations that determine energy performance against the energy policy and objectives and report the results.

Act:

take actions to continually improve energy performance and the EnMS.

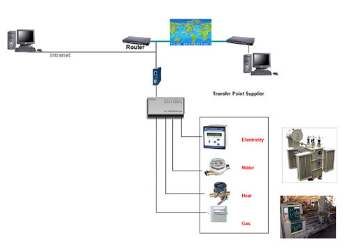

Energy Management System - “The Entire Plant @your Finger Tips ....”

Energy Management System - “The Entire Plant @your Finger Tips ....”

It is wise to install an Energy Management system in the plant to monitor and record the energy consumption from all the load centers. An energy management system can provide accurate energy consumption data to the maintenance and management personnel to monitor and control the consumption.

Unless We Measure We Cannot Monitor...!!!

Unless We Control We Cannot Survive...!!!

| Image | Instrument | Model | Range | Application |

|---|---|---|---|---|

|

PQ Analyser | HIOKI-3197 | 690V/5000AC/LV SYSTEM | Power Quality Analysis |

|

Energy/Harmonics Meter | Meco 4545 | 1000v AC/1500A/99th Order | Energy / Harmonics Study |

|

Thermal Imager | Testo 875 | 9Hz/320x240 Pixels/Upto 280°C | To find Hot Spots in Electrical distribution & Equipments |

|

Comp. Air Data Logger | VP Flow Scope | Upto 150 nm/Sec & 16 Bar To Analyse & Record | Compressed Air Flow / Pressure / Temperature |

|

Testo 330 | Kane Intl-U.K - 940 | SO2/NOX/O2/CO/CO2. Excess Air & Efficiency | To analyse Boiler Performance |

|

Ultrasonic Leak Detector | EXAIR-USA 9061 | 20KHz-100KHz / Max 6 Meters Distance | To find out Air/Steam Leaks in the System |

|

U Tube Manometer | NA | 460mmWC | Differential Pressure Measurement |

|

Anemometer | Lutron - AM-4201 | Upto 30m/sec | Air Velocity Measurement |

|

Lux Meter | Kusa Meco KM-100K | Upto 100,000 lux | To measure Lux level of a Lighting System |

|

Ultrasonic Leak Detector | EXAIR-USA 9061 | 20KHz-100KHz / Max 6 Meters Distance | To find out Air/Steam Leaks in the System |

|

Tachometer (Non-Contact) | KM 2234 BL | 5-9999 RPM | To measure RPM of a revolving equipment |

|

IR Thermometer | Fluke 570 | Upto 900°C | To measure Temperature of a point/Joint/Equipment |